- Overview

- Inquiry

- Related Products

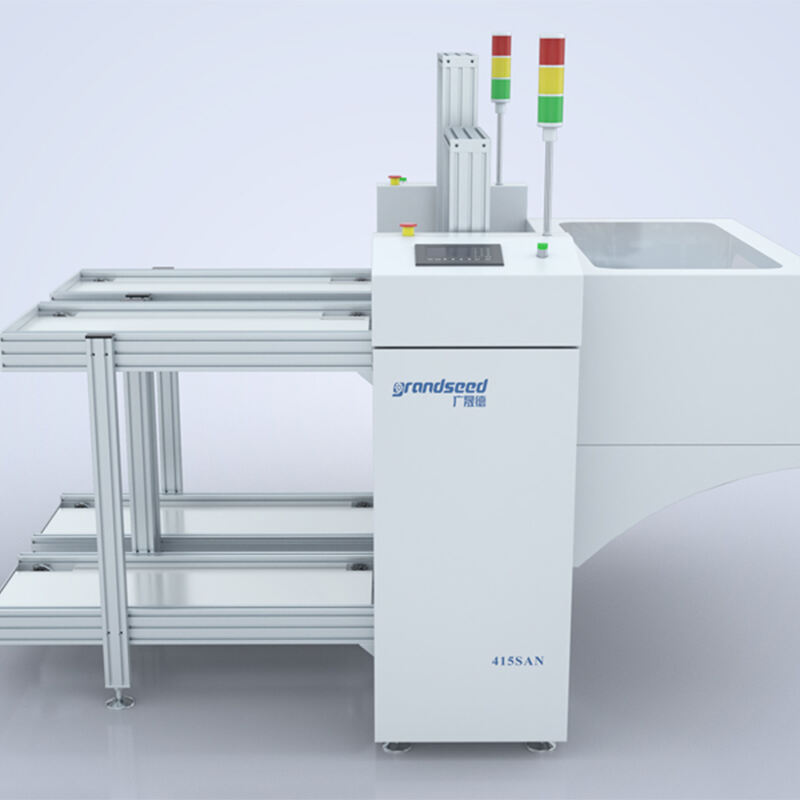

Product Features:

Touch screen display, PLC control, menu operation interface, easy to operate;

A wide range, you can use a standard rack, versatile, the max capacity 6 racks ;

Rack can be set according to PCB lifting step height or thickness;

Auto production and yield statistics query;

With standard signal communication lines, easy to connect with each other and other SMT Equipment.

| Specification: | |

| Item | Auto Unloader equipment |

| Control method | PLC(Siemens) |

| PCB size | 50*50*0.8mm—W460*L535*2mm |

| Transport high | 900±20mm |

| Transmission direction | L→R(R→L) |

| Step choose | 10/20/30/40 |

| Rack Specifications | 535mm*460mm*563mm |

| Power supply | AC220V 50HZ |

| Air pressure | 5—7kg/cm2 |

| Dimension | 3250L*940W*1250H |

| Weight | 320KG |

Features:

Durable and stable sheet metal main frame design,

Effective cylinder push plate design ensures that the PCB board is not damaged by pushing

Human machine touch screen operation interface, highly simple human-machine dialogue, easy to operate and understand

Panasonic PLC program control, multifunctional circuit and program design, stable performance, ensuring smooth and smooth production line, and maximizing production capacity

Humanized programming design, 5 pitch options, and the ability to set the spacing between push PCB boards

Capacity setting can achieve planned production control (sound and light prompts)

Sound and light alarm system, human-machine interface screen abnormal information prompt, maintenance is simpler and more convenient

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

BE

BE

MK

MK

AZ

AZ

BN

BN

LA

LA

MN

MN

NE

NE

TA

TA

UZ

UZ

XH

XH